We will continue with our Seminar Series on September 18th, 2023

On site: Salón de Grados Leganés

Online:

For the next event in the Aerospace PhD Seminar Series, we will have the pleasure of hosting Prof. Dr. Andy Gleadall professor at Universidad de Loughborough

The event will take place in the Salón de Grados on Monday, September 18th at 1pm and will be streamed.

Andrew Gleadall studied for a mechanical engineering PhD at the University of Leicester, researching the degradation of mechanical properties of bioresorbable medical polymers. After his PhD, he joined the University of Nottingham, where he researched hybrid manufacturing and additive manufacturing of tissue engineering constructs. In 2017 he joined Loughborough University as a lecturer and became a senior lecturer in 2021. He’s been researching the extrusion 3D printing process for 10 years and has been creating custom toolpaths from almost the first time he used a 3D printer. A key area of research has been in the mechanical characterisation of bond strength between 3D printed layers. He has published multiple papers highlighting that microscale geometry is the most important factor for mechanical performance. Even more important than the intermolecular diffusion of polymer chains, which is commonly stated to be the cause of interlayer weakness, but without direct supporting evidence at the molecular scale. The focus on the critical role of geometry and led him to develop models to predict microscale geometry: https://doi.org/10.1016/j.addma.2018.04.004

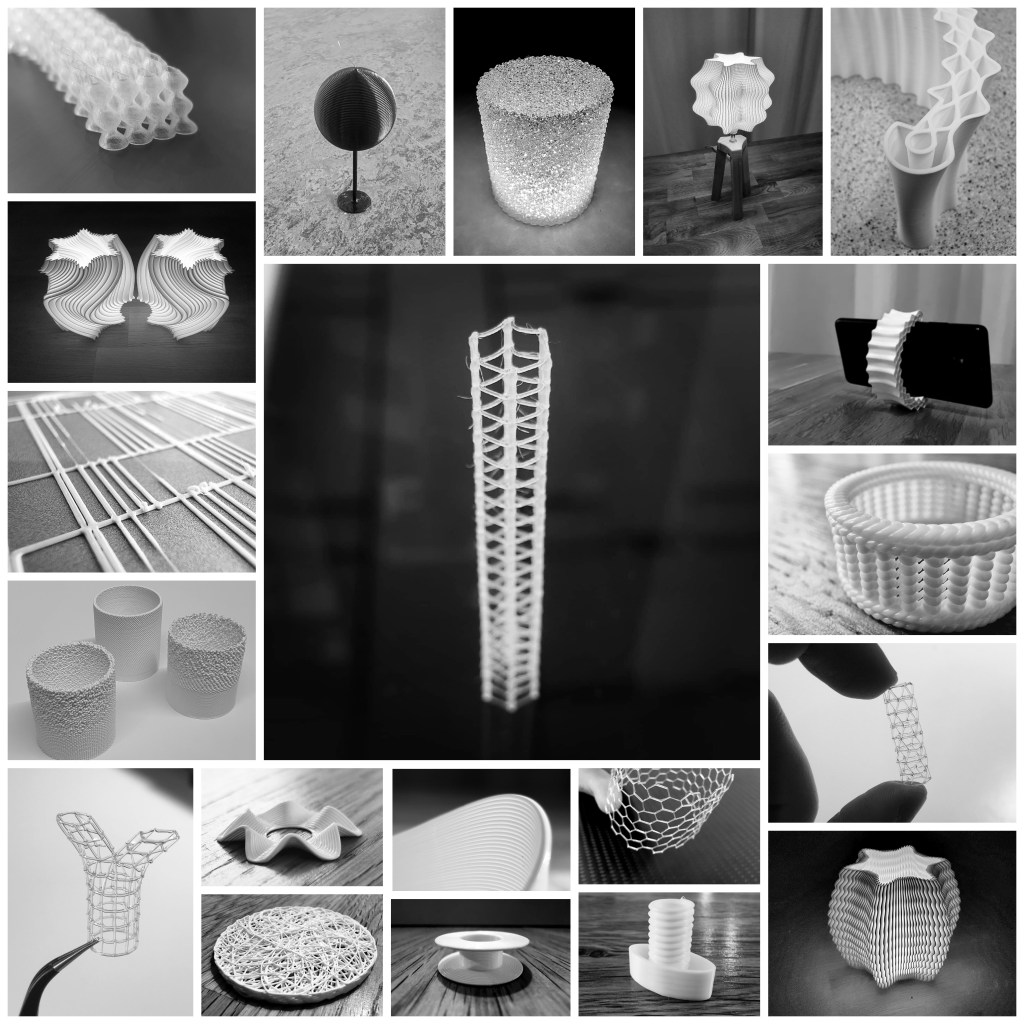

“Custom toolpaths for additive manufacturing: pharmaceuticals, tissue engineering, robotics, concrete, mechanical optimisation and more”

Abstract:

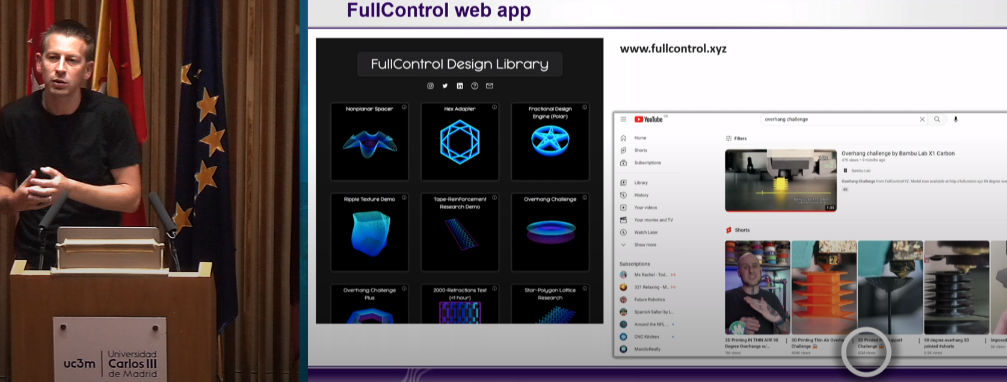

He has also developed software for the direct design of custom toolpaths: https://doi.org/10.1016/j.addma.2021.102109 / https://www.youtube.com/watch?v=KlxuZ5JnA0k / https://www.youtube.com/watch?v=yGtyw3oLOVQ

It allows much more control over the printing process and replaces the entire conventional workflow of: create a 3D model -> export as an STL file -> slice into layers -> generate a print path for each layer -> generate gcode.

The initial version of the software utilised an Excel front-end to ensure accessibility to researchers without programming skills. Subsequent releases of the software utilise Python for toolpath design: https://github.com/FullControlXYZ/fullcontrol

The software has led to his involvement in a diverse range of projects including pharmaceutical pills, wound dressings, medical braces, tissue engineering scaffolds, and the 3D printing and machining of concrete. He has extended the software from 3-axis systems to multi-axis 3D printers and robots. The python version of the software powers an associated website (https://fullcontrol.xyz), that directly generates manufacturing procedures in the web browser and allows additive manufacturing of structures that are conventionally believed to be impossible. The demo designs have been used by hardware developers (e.g. Bambu Lab, Duet3D, Direct3D) and covered by high-profile social media influencers (e.g. https://www.youtube.com/shorts/c9b7Ey4LyCs)

This talk draw use examples from existing projects in the range of fields mentioned above to discuss the potential value of custom toolpaths.

The seminars will begin at 1pm and will take place in the Auditorium Salón de Grados (Padre Soler)

No previous registration is required.